It consists of several different material parting operations such a piercing perforating shearing notching cutoff and blanking.

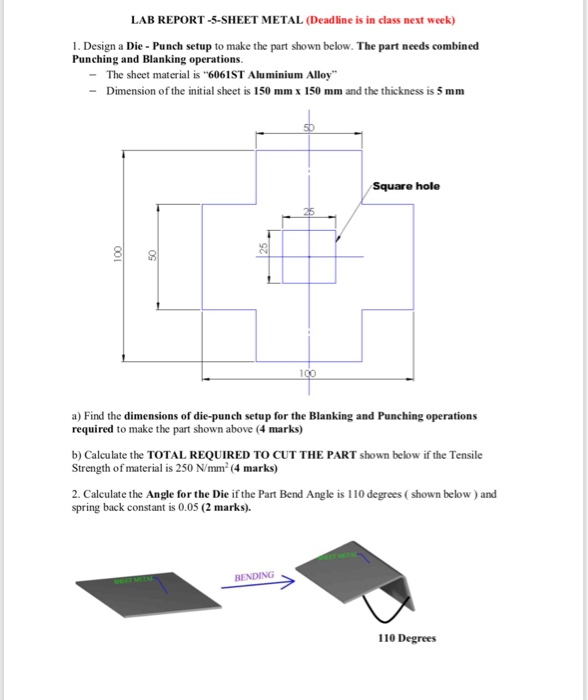

Design of sheet metal blanking and piercing dies.

Stamped components are made by forming drawing trimming blanking or piercing metal in sheet or coil form between two halves upper and lower of a press tool called a die.

Dies design cutting operations part 2 1.

In blanking the portion of material which is cut out from the sheet is the required part.

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock.

The purpose of blanking is to get the part inside the closed contour.

Difference between blanking and piercing.

They may be simple combination or compound.

Punching blanking and piercing are sheet metal shearing operations to modify existing blank.

The blank dimension is determined by the die size.

The mold for blanking is been called blanking die.

In this die the die block assembly is mounted on the bolster plate or the press bed and the punch assembly on the press slide.

A single blanking die can produce.

The purpose of piercing is to get a part outside the closed contour.

It is one of the most extensively used processes throughout die and sheet metal work.

In blanking the piece is cut off from the sheet and it becomes a finished part.

We suggest you read sheet metal design guidelines to understand in detail about sheet.

As i said earlier both are metal shearing operations used for cutting sheet metal.

The die is designed to create the shape and size of a component.

Whereas in piercing the portion which is punched out from the sheet is scrap.

Same machines can be used to perform these operations.

The web is created after multiple components have been produced and is considered scrap material.

The major differences are as follows.

The monthly volume of component is 4000 to 6000 nos.

Both blanking and piercing utilize a mold to separate a portion of the sheet from another portion along a closed contour.

The upper member or members are attached to slide or slides of the press and the lower member is clamped or bolted to the bed or bolster.

These all operations need be combined in a single setup of die punch with a proper tool design.

Blanking and punching dies.

2 5 blanking die and piercing die design.

Blanking and punching dies are known as cutting dies.

Types of blanking dies there are two general types of blanking dies.

Sheet metal forming processes and die design.

Problem statement the aim of this project is to reduce cycle time of existing process of milling blanking and drilling operation for component.

The drop through dies and the inverted dies.

A blanking die is generally cheaper to make and faster in operation than a trim die.

In this article we will discuss how blanking punching and piercing operations are different from one another.

Handbook of die design suchy sheet metal forming knowledge base sme fundamentals of tool design sme 2.