This process involves the use of smooth rotating tool to carry out local sheet metal deformation without use of expensive die.

Development of process control in sheet metal forming.

Joins the punch line to the blankholder with an opening.

Sheet metal forming process is done on a press and the parts are formed in between two die.

Isf is a cold forming process developed in japan to satisfy the need of automotive industries.

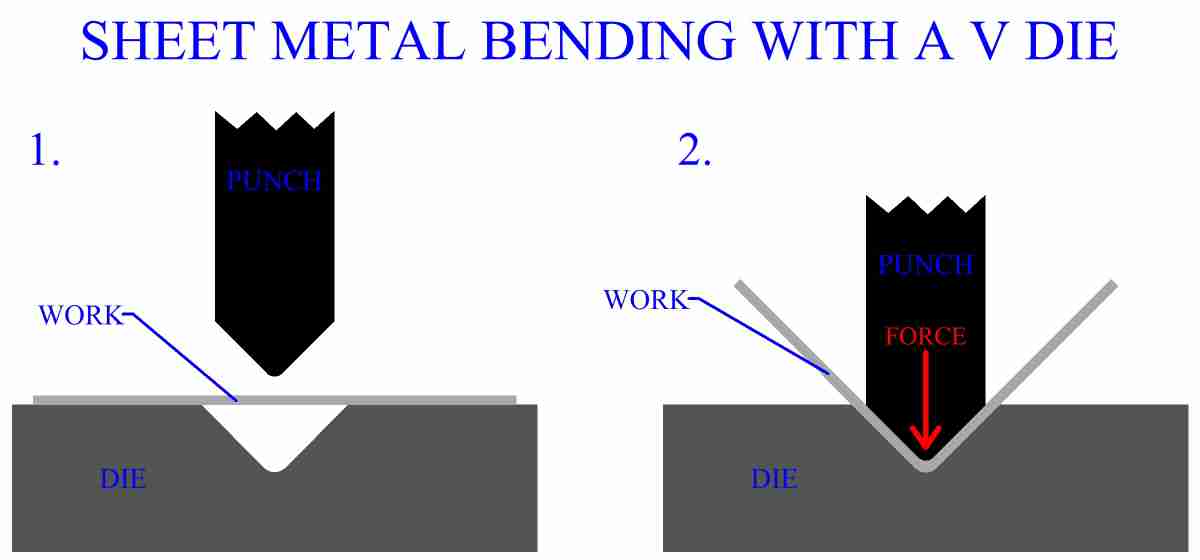

Another common sheet metal forming process is bending.

Most problems in sheet metal forming come from a bad control of holding restraining and springback.

Process design is the ensemble of operations leading from the design geometry to.

Development of process control in sheet metal forming.

Sheet metal forming processes.

Companies typically perform bending on sheet metal using either a brake press or similar machine press.

The sheet metal is placed over a die block at which point a punch presses down.

The die at the top is called a punch.

Sheet metal stamping is one of the primary manufacturing processes because of its high speed and low.

Process control in sheet metal forming.

This is the reason isf is also known as die less forming method sayed mojta 2014.

Process control experiments were conducted on a double action hydraulic.

In this paper an innovative method was proposed to change the loading path by using a property adjustable flexible die mr fluid in sheet forming process.

Curling is a forming process that involves de burring sheet metal to produce smooth edges.

Flange development and protection die entry line.

In sheet metal forming operations the loading path is a significant process parameter which greatly influences material flow and part quality.

Process control can be used to adjust the blank.

Sheet metal is formed cold.