Tempered safety glass has an impact strength that s five times higher than normal annealed glass of the same thickness while lexan has an impact strength that s 250 times that of annealed glass.

Difference between safety sheet glass and safety plate glass.

Laminated glass is safety glass because if broken the glass stays bonded to the plastic sheet that is between two separate lites of glass.

Safety glass is not as strong.

Although the plate glass process was replaced by the float glass method in the 1960s people still tend to refer to a large flat pane of unstained glass.

Large sheets of glass for storefronts and shop windows were made this way and the same technology was used to make mirrors.

Other thicknesses are available.

Laminated glass is made by using a plastic film or resin to adhered two pieces of glass together.

It is usually about 3 32 for single strength glass.

Safety glass is a type of glass made in such a way that it is less likely to cause injury if it breaks.

It is usually 3 16 thick.

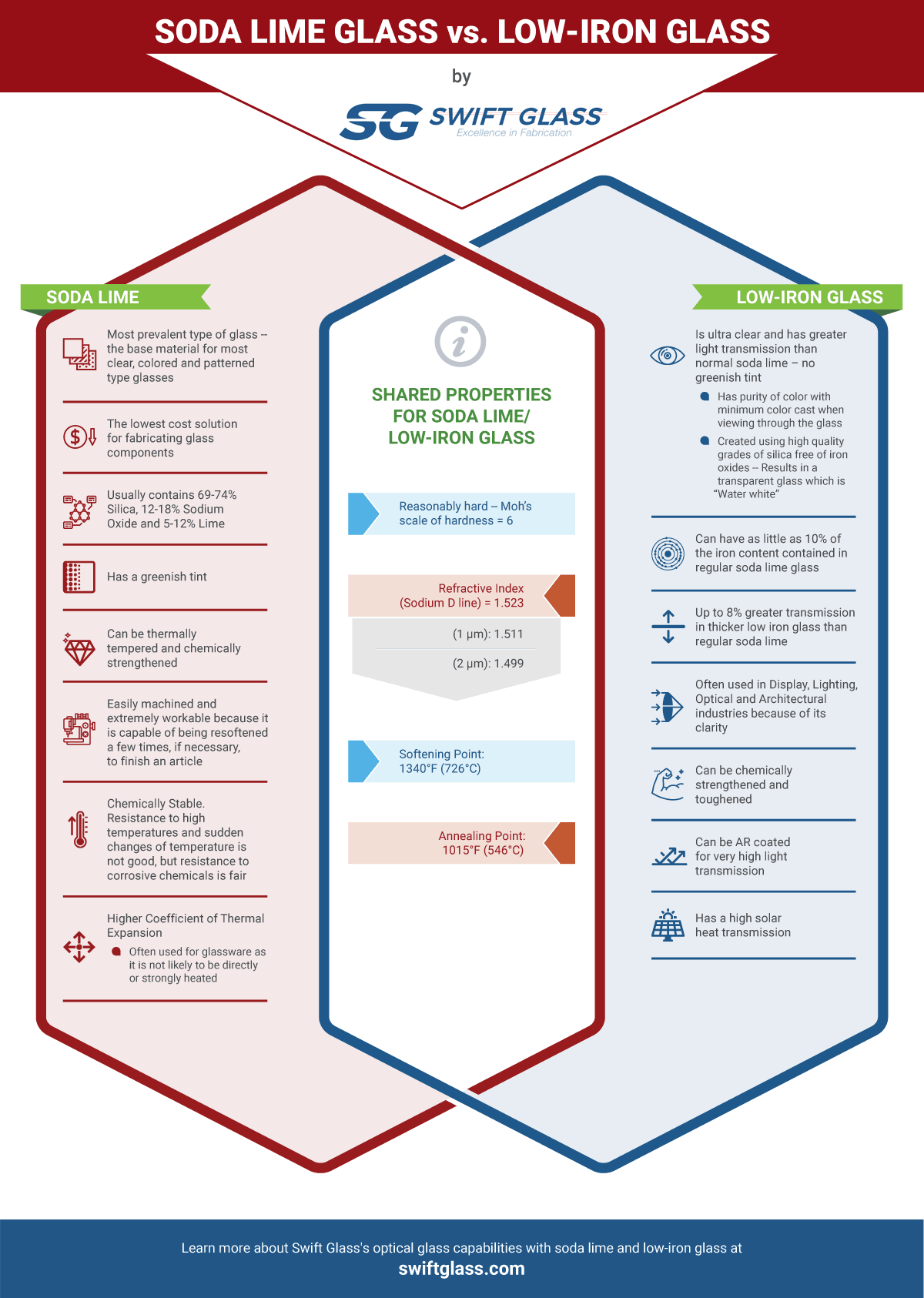

The main difference between these two types of glass is how they are made.

Because lexan is so strong it can also be manufactured into thinner sheets that don t weigh as much as safety glass.

It provides a clear view without distortion.

Safety glass is also known as laminated glass and this is because of the process used to make it.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Sheet glass is the most common glass.

Plate glass is generally used for large picture windows.

Tempered glass is one of the most well known forms of safety glass but it s not the only one.

Safety glass can also be laminated engraved and made of wire mesh.